Building custom magnetic field coils, pulsed power systems, and scientific instrumentation since 2005

Controls and Data Acquisition (DAQ)

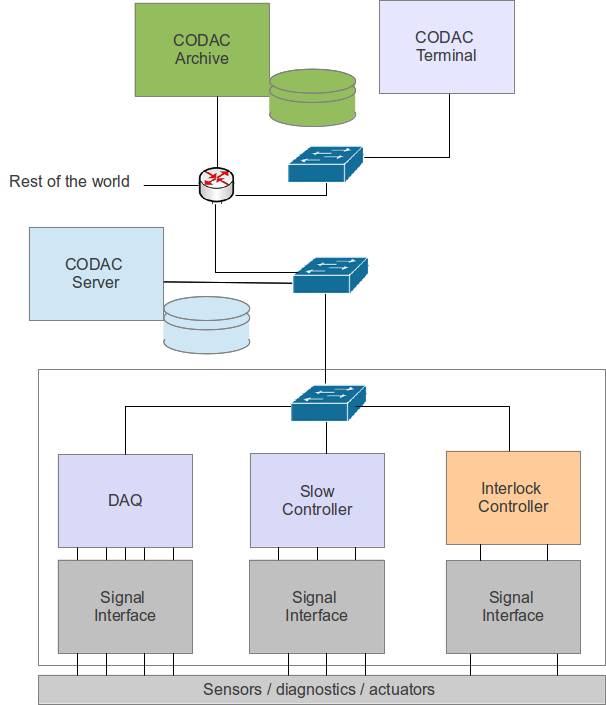

Controls, Data Acccess and Communication (CODAC) is the oft-used term for the systems that gather and analyze data and sends signals to all systems in order to measure critical physics parameters, control the plasma and to maintain safe operation of the device. The main components of a data acquisition and control system are

- sensors to measure some control parameter

- an analogue to digital converter to convert signal into a form that can be either stored or acted on

- programming logic to control the variable

- output instrumentation for controlling the parameter.

Applications for controls are wide ranging. The aerospace industry has the most overlap with fusion research, since most subsystems are used in electric propulsion, pulsed plasma thrusters and even fusion propulsion. Next most closely related to fusion systems are military applications, particularly for electromagnetic launchers (projectiles, aircraft, etc), rail-, electrothermal- or coil-guns, high power microwave generators (explosive flux compression generators) and most high power laser. R&D applications include lightning simulators, linear accelerators, plasma switches.

WSI can help you design and install your CODAC system.

“Woodruff Scientific have made an excellent complete control and data acquisition system for our Laboratory Astrophysical Jet experiment. The system was expertly tailored to our needs with COTS National Instruments and proprietary custom hardware, operated by a full set of LabView interfaces coded to best practise design patterns. The hardware and services provided by Woodruff Scientific are among the most cost-effective in the industry. Highly recommended.”

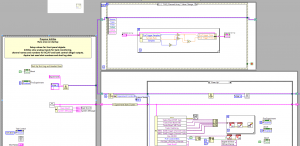

LabVIEW Experiment Management System

WSI uses National Instruments LabVIEW for experiment control.

Our software includes:

- Integration with safety interlocks

- Control of charging & firing of banks (PXI Star high-performance trigger signaling <1ns inter-module delay)

- Read in of data channels and export of data (csv, MDS+, etc.)

- Real time abort

- Expandable, customizable, and compatible with NI equipment

A basic version of the Experiment Management System is available free of charge:

If you need further assistance using or configuring the Experiment Management system, let us know. WSI can also modify the experiment management system to better suit your lab. Let us know what modifications you need.

| Products | Model Number | Spec Sheet | References | |

| CODAC | Request spec sheet | Get a Quote » | ||

| LabVIEW Experiment Management System | Request spec sheet | Get a Quote » | ||

| Data Acquisition and Control | Request spec sheet | Get a Quote » | ||

| Fiber-Optic Relay Controls | Request spec sheet | Get a Quote » | ||

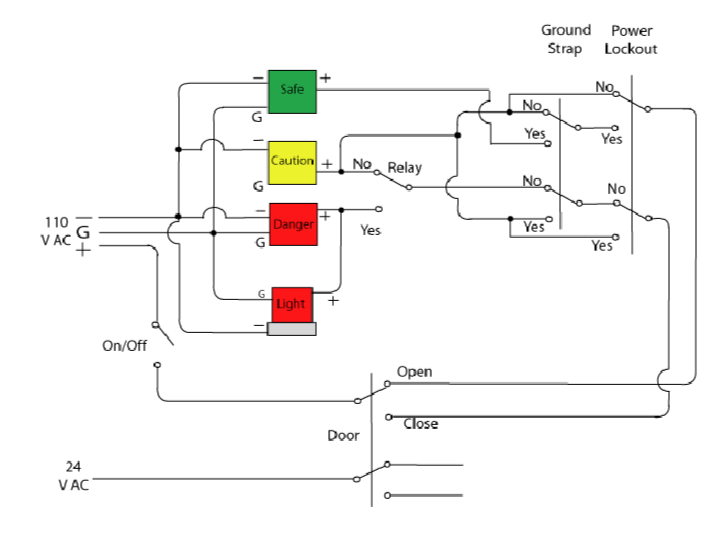

| Safety Interlocks | Request spec sheet | Get a Quote » |

Data Acquisition and Control

WSI uses National Instruments hardware for data acquisition. We can tailor hardware setups for your lab.

Minimum data acquisition/controls for use with Experiment Management System: MinDAQ. Simple 24 channel 3MHz system.

Concept Exploration data acquisition and controls for use with our Experiment Management System: CEDAQ. 80 channels of 3MHz with 8 of 60MHz.

Minimalist-looking Proof of Principal data acquisition and controls for use with our Experiment Management System: CEDAQ base and extra data channels for POP level system. In total there are 176 channels of 3MHz and 24 of 60MHz.

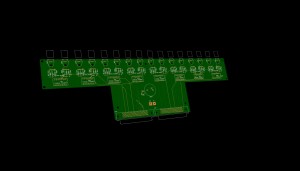

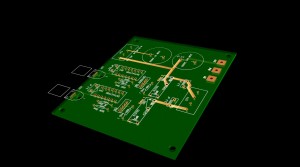

Fiber-Optic Relay Controls

Fiber-Optic Control relays:

- For charge, dump, any signaling within an enclosure

- Emitter boards connect to NI equipment

- Boards can be enclosed in 1U rack-mountable units, or any custom enclosure

- Fully customizable to spec

Safety Interlocks

Safety interlocks along with a proper safety plan can help reduce the chance of lab injury. Our interlock system can be integrated with the experiment control system. WSI can work with your lab to develop room layouts, safety interlocks, and safe operations procedures.